-

AboutShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

-

ProductShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

-

Core AdvantagesShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

-

CasesShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

-

Customer serviceShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

-

ContactShenzhen Century Bailey Environmental Protection Technology Co., Ltd. (referred to as "Century Bailey") is located by the Guanlan Lake of the World Golf Village, adjacent to the Shanshui Tianyuan Tourism and Culture Park. It is a national high-tech enterprise and a specialized and new enterprise focusing on the research, development, production, and sales of catering industry oil fume purification products.

Shenzhen East Station and Shenzhen oil fume purifier manufacturer Century Bailey join forces

Product overview:

Catalog:

Keyword:

Shenzhen East Station and Shenzhen oil fume purifier manufacturer Century Bailey join forces

Keywords:

Product features

Shenzhen East Station did not install the Century Bailey system Integrated oil fume purification machine Previous situation introduction:

After the renovation of the former Buji Railway Station, it was put into use on December 21, 2012, and is now in operation. Shenzhen East Station is located east of Longgang Avenue and west of Ji Hua Road, with a total area of approximately 127,000 square meters. It is the first station for outsiders entering Shenzhen and the city's gateway. Catering within the station is undoubtedly crucial, and emissions are the biggest problem. The building design lacks main pipelines for the discharge of catering oil fumes.

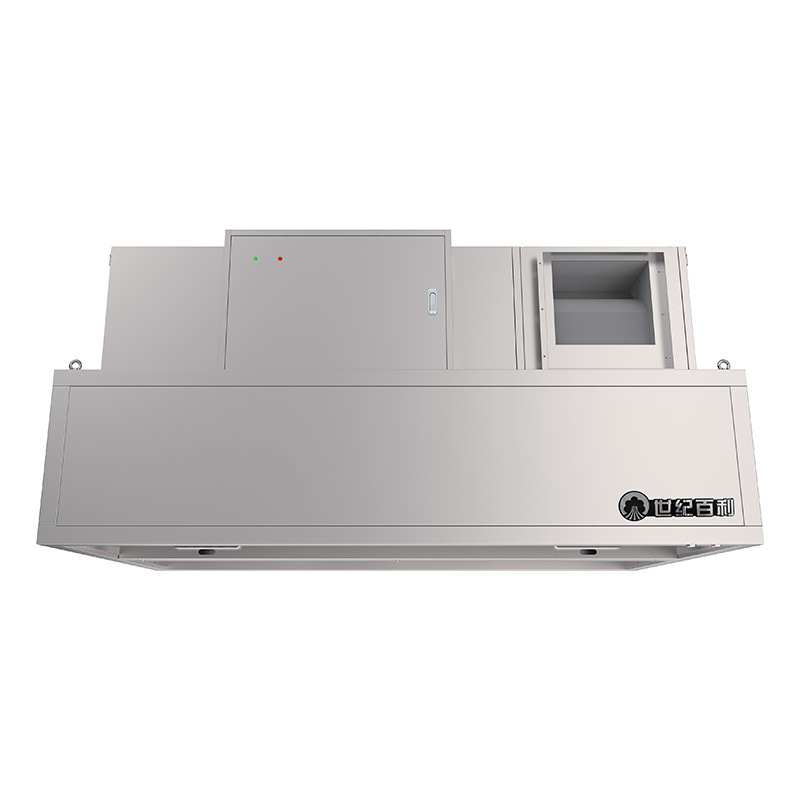

Shenzhen East Station installed the Century Bailey system Integrated oil fume purification machine Actual effect diagram.

Introduction to the situation after Shenzhen East Station installed the Century Bailey integrated oil fume purification machine:

In order to solve the complex problems of Shenzhen East Station, Shenzhen Oil fume purifier manufacturer Century Bailey ultimately recommended the integrated oil fume purification machine to help the East Station solve the problem of low-altitude emissions.

This integrated oil fume purification machine uses a special purification agent to improve the double-film mass transfer driving force between the gas and liquid phases, which can quickly capture oil fumes and other particles in the gas phase;

At the same time, it uses the negative pressure of its own exhaust fan to generate a liquid droplet layer of about 600 mm thick (liquid droplet diameter 1.5 mm) to perform washing purification on the oil fume gas. This is approximately equivalent to the purification effect of a natural rainfall layer 600 meters high.

Technical parameters

Application cases

Product consultation

Note: Please leave your email address, our professionals will contact you as soon as possible!

Hotline:+86 755-83665285

Email:sjblsz@163.com

Address:No. 6, Junzibubujun New Industrial Road, Guanlan, Longhua New District, Shenzhen

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home